Progressing Cavity Pumps are rotary positive displacement pumps. The main component, a metal rotor, which is in the shape of a single external helix, rotates around its on axis in the direction of rotation (say clockwise); while the axis of the rotor, revolves in the opposite direction (say anticlockwise) around the axis of the stator. The stator is made of and elastomeric bonded to end alloy steel tube. The stator itself is in the shape of an internal double helix. The rotor is contained within the stator and forms a continuous seal along the length of the stator. The above movement produces cavities at reduced pressures which move axially from the inlet to the outlet conveying the fluid at fixed flow rate proportional to the rotational speed.

Features :

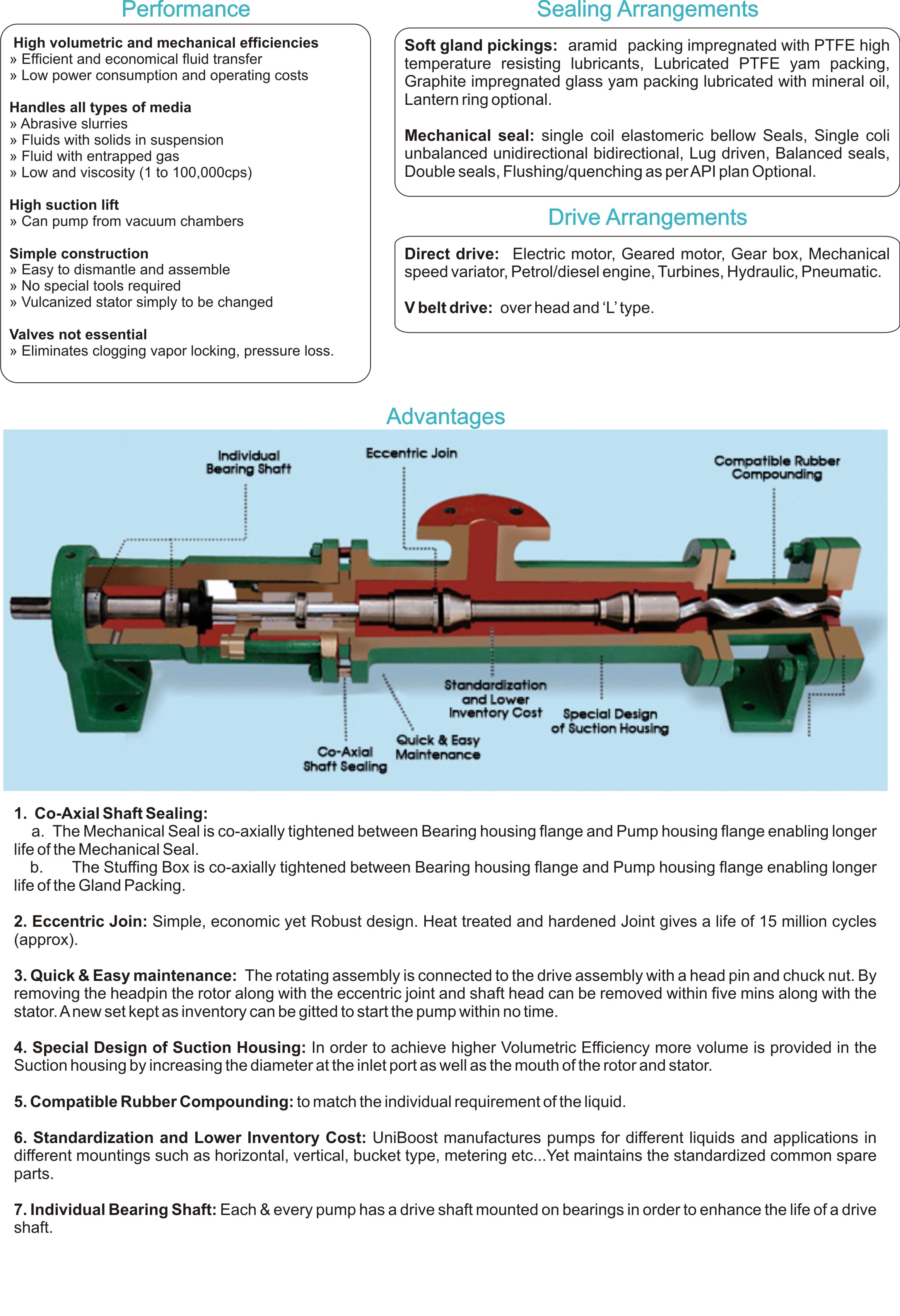

> Abrasion resistant chrome plated rotor

> Stator elastomers to suit specific requirement

> Wide range of material of construction

> Hardened bush pin type universal joint sealed and grease lubricated

> Heat treated, hard chrome plated drive shaft

Specification :

UBH Series: Standard S Series

Capacity: upto 250 m3/hr Head 12 kg/cm2

Capacity: upto 72 m3/hr Head 24 kg/cm2

UBH AG Series: Sugar Type S Series

Capacity: upto 250 m3/hr Head 12 kg/cm2

Capacity: upto 72 m3/hr Head 24 kg/cm2

UBH VT Series: Vertical Type S Series

Capacity: upto 72 m3/hr Head 24 kg/cm2